LED Driver Waterproof IP67 Power Transformer Adapter

Safety

Automatic protection for Short circuit / overload / over voltage / over current / over temperature.

Protection type: Hiccup mode, auto-recovery after fault condition is removed.

Features

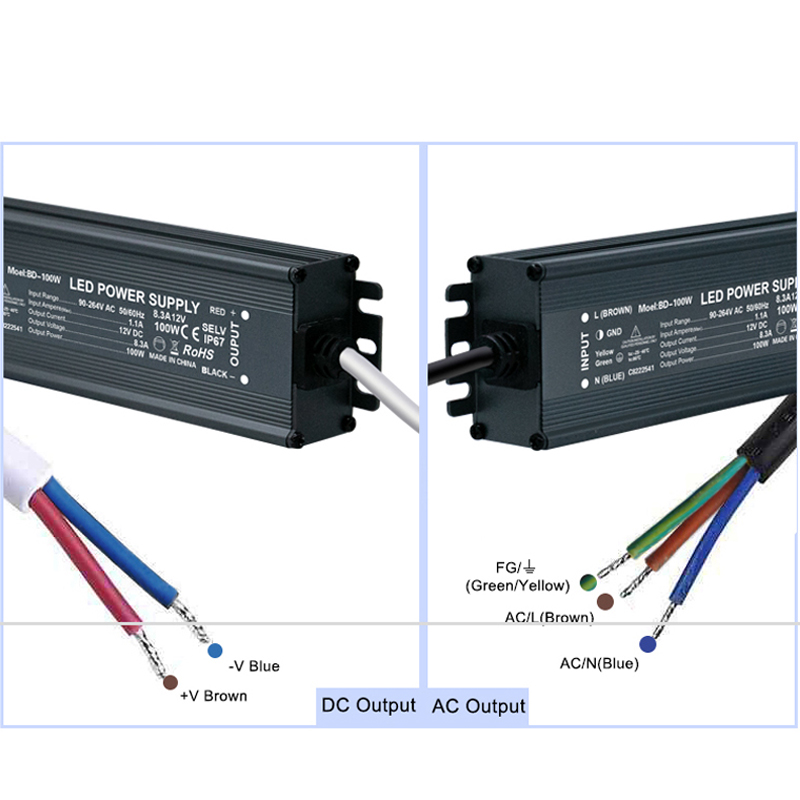

Constant voltage style power supply and Universal AC input/Full range.

Cooling by free air convection and Fully encapsulated with IP67 level.

100% full load burn-in test. Small volume, low weight and high efficiency.

Protections for short circuit, over load, over voltage and over temperature.

● Featured high-voltage materials

Product Specifications

● Input: 100-260V AC 50/60HZ

● Output: 12V DC 10A

● Wattage: 120W

● Working Temperature: -40℃ to +50℃

● Working Relative Humidity: 10%-100%Rh

● Dimensions: 7.72*2.71*1.65inch

● Waterproof: IP67

● Input Efficiency: 87%

● Weight: 2 pounds

100% full load aging test, short circuit, overload, over voltage, overheating automatic protection, with efficient and reliable IC solution.

Waterproof IP67 grade, LED Driver adapter is made of aluminum alloy casing, easy to dissipate heat, easy to install, ensure long stability and long life

Wide range of LED power supplies: suitable for LED lighting, security cameras, CCTV, LED strips, LED bulbs, computer projects, industrial, outdoor lights and any 12V DC LED lights comply with global lighting safety regulations, compatibility, no flicker

The LED driver is NOT dimmable, the LED driver is only compatible with RGB dimmers.LED transformer certification: IP67,CE,ROHS SELV etc

Making a waterproof power supply usually requires considering waterproofing, insulation and safety properties. The following are the general steps for the manufacturing process of a general waterproof power supply: Choose a waterproof material: Choose a case material that meets waterproof standards, such as a waterproof plastic or waterproof metal case. Design a waterproof structure: Design a reasonable waterproof structure, including sealing rings, waterproof glue, waterproof interfaces, etc., to ensure that the internal components of the power supply are not affected by moisture. Install power components: Install power components such as transformers, rectifier circuits, filter circuits, etc. into the waterproof enclosure and secure them well. Wire treatment: Waterproof the wires entering and exiting the power supply, usually using waterproof connectors or waterproof glue seals. Test acceptance: Conduct circuit connection and performance tests on the assembled waterproof power supply to ensure that it works properly and meets waterproof standards. Product packaging: The waterproof power supply that has passed the test is usually packaged with a waterproof logo or waterproof instructions. It should be noted that when making a waterproof power supply, it is also necessary to comply with relevant electrical safety standards and waterproof grade standards to ensure that the product meets the prescribed safety performance and waterproof requirements. During the production process, special attention should be paid to the process and material selection of the waterproof part to ensure the overall waterproof performance.

Professional

We have 4 after-sales customer service to provide you with 24-hour online answers.

Fast

Our own mold workshop make custom mold samples fast and coordinate.

Experience

We have 11 years manufacturing experience,corporate suppliers provide the raw material in time.

Service

Some of our customer have cooperate with us for 10 years because of quality and nice after service.

Production equipment

There are different kinds of machines for producing, many standard types goods with bulk stock for fast delivery.

Testing Center

Each product has been tested many ours before shipment.

New Open Led Sign

New Open Led Sign Led Module

Led Module led Signage

led Signage led Neon Light

led Neon Light Led Strip

Led Strip Led Pixel

Led Pixel Led Power Supply

Led Power Supply Neon Sign

Neon Sign